Braking performance is crucial to vehicle safety, influencing stopping distances, control, and overall driving experience. One of the most effective ways to enhance braking efficiency is upgrading to grooved rotors. These specialized brake rotors feature precision-cut grooves that help dissipate heat, reduce brake fade, and improve braking responsiveness. This article will explore how grooved rotors work, their advantages, and why they are popular among performance-oriented drivers.

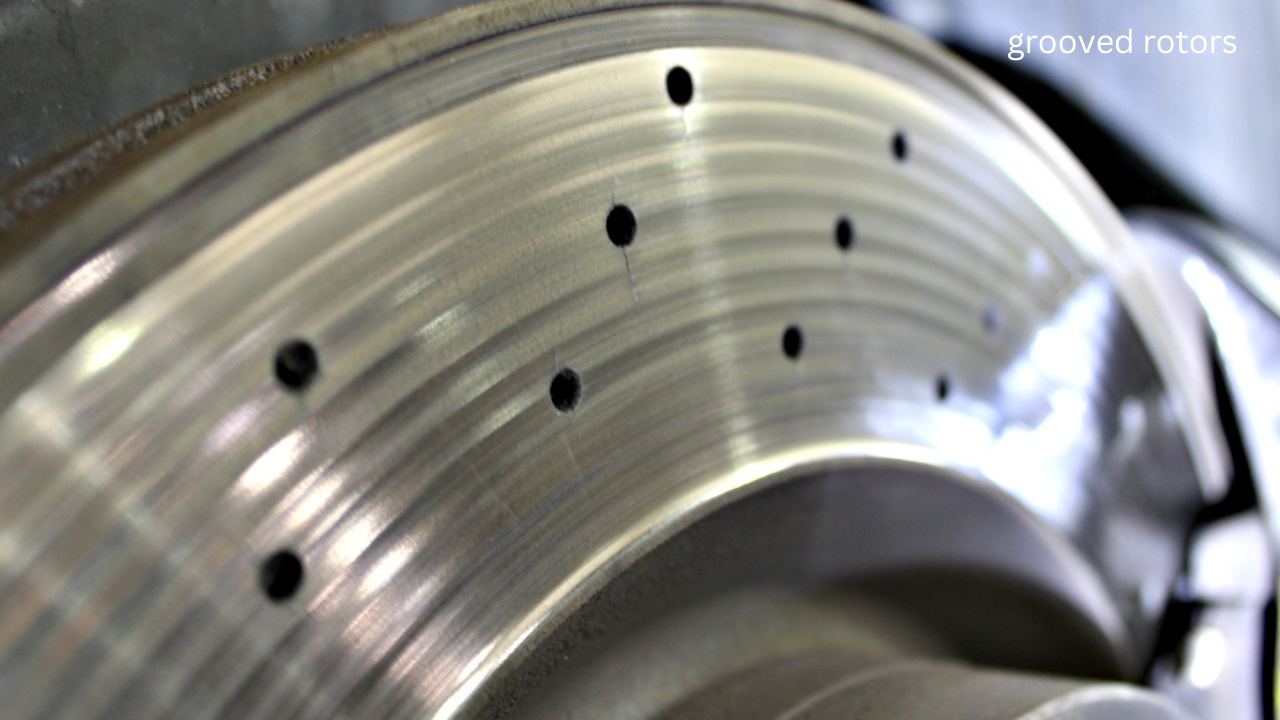

What Are Grooved Rotors?

Grooved rotors, also known as slotted rotors, are brake rotors that have small, linear channels (grooves) cut into their surface. These grooves enhance braking efficiency by improving heat dissipation, reducing brake pad glazing, and maintaining optimal contact between the brake pads and rotors. Unlike solid or drilled rotors, grooved rotors prioritize cooling and performance under extreme conditions. Grooved rotors allow a small amount of brake pad material and gas to escape through the grooves. When braking, friction between the brake pads and rotors generates heat and debris. Without proper ventilation, this can lead to brake fade, a condition where braking efficiency is reduced due to excessive heat buildup. The grooves on the rotor help to expel excess gases between the pad and rotor, prevent brake pad glazing, which occurs when pads overheat and form a hard, ineffective layer, and improve bite and grip by maintaining a cleaner contact surface.

Key Benefits of Grooved Rotors

Improved Heat Dissipation

Heat is the biggest enemy of braking performance. When brakes overheat, they lose effectiveness, leading to longer stopping distances. Grooved rotors help dissipate heat more efficiently by increasing the rotor’s surface area and allowing air to flow through the grooves. This helps keep braking temperatures within an optimal range, especially during aggressive driving or high-speed braking.

Reduced Brake Fade

Brake fade occurs when excessive heat buildup reduces the friction between brake pads and rotors, resulting in poor braking performance. Because grooved rotors help keep the braking surface cooler, they significantly reduce brake fade, making them ideal for performance vehicles, sports cars, and racing applications.

Enhanced Brake Pad Performance

One significant advantage of grooved rotors is their ability to prevent brake pad glazing. Excessive heat can cause brake pads to develop a hardened layer over time, making them less effective. The grooves help scrape off this layer, ensuring the pads maintain their friction properties and provide consistent braking performance.

Better Water and Debris Evacuation

Driving in wet or dirty conditions can cause water, dust, and debris to accumulate on the brake rotors. Grooved rotors help channel away water and contaminants, reducing the risk of hydroplaning on the braking surface and maintaining strong stopping power even in adverse conditions.

More Consistent Braking Feel

Since grooved rotors help maintain an optimal braking surface by clearing debris and preventing uneven wear, they produce a more predictable and consistent braking response. This is particularly beneficial for track racing and spirited driving, where precise braking control is essential.

Grooved Rotors vs. Drilled Rotors: Which Is Better?

When upgrading brake rotors, drivers often compare grooved vs. drilled rotors. Both have unique advantages. While drilled rotors are known for their lightweight and aesthetic appeal, they are more prone to cracking under high stress. Grooved rotors, on the other hand, are designed for durability and superior performance, making them a preferred choice for high-performance applications.

Are Grooved Rotors Right for You?

Grooved rotors are ideal for performance enthusiasts who demand the best braking performance, track day drivers who experience extreme braking conditions, heavy vehicles such as trucks and SUVs that need improved stopping power, and drivers in wet or dusty environments where debris clearance is necessary. However, they may not be required for everyday commuter vehicles that rarely experience intense braking conditions.

How to Maintain Grooved Rotors

To maximize the lifespan and performance of grooved rotors, follow these maintenance tips: Use high-quality brake pads to ensure optimal braking efficiency, regularly inspect for uneven wear patterns or deep grooves that may affect braking performance, keep rotors clean to remove brake dust and debris, avoid aggressive braking when cold to prevent premature wear, and bed in new rotors properly by following the manufacturer’s bedding-in procedure to ensure even wear and peak performance.

Conclusion

Grooved rotors are a highly effective upgrade for drivers looking to improve their vehicle’s braking performance, heat dissipation, and overall safety. By reducing brake fade, preventing pad glazing, and maintaining consistent stopping power, these rotors provide a superior braking experience, especially for high-performance applications. Grooved rotors are worthwhile if you prioritize safety, durability, and optimal braking.

FAQs About Grooved Rotors

Do grooved rotors wear out brake pads faster?

Yes, grooved rotors can cause slightly faster brake pad wear than standard rotors because they continuously scrape the pad surface to remove debris and prevent glazing. However, this also ensures better braking efficiency.

Are grooved rotors suitable for daily driving?

Grooved rotors can be used for daily driving, but they are more beneficial for performance and heavy-duty applications. If your driving conditions involve frequent braking, they can enhance safety and durability.

Can grooved rotors be resurfaced?

In most cases, grooved rotors can be resurfaced, making the grooves shallower to reduce their effectiveness. However, if they are excessively worn, it’s often better to replace them.

Do grooved rotors make noise?

Some grooved rotors can produce a slight whirring or humming noise, especially when braking hard. However, this is normal and usually a sign that the grooves are effectively clear debris.

How long do grooved rotors last?

The lifespan of grooved rotors depends on driving conditions, braking habits, and maintenance. On average, they last 30,000 to 70,000 miles, though high-performance use may lead to faster wear.

You May Also Read: https://usdigitaltime.com/valvoline-prices/